Scrum Vs. Kanban Know the Difference Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Home; Kanban Tutorial ; Kanban Tutorial. All Tutorials; Job Search; What is Kanban? Kanban is a kind of management tool for groups and companies to anticipate their work, recognize and abolish hurdles and succeed in achieving better …

Kanban process SAP Blogs

www.agileinnovation.eu. What is Kanban for Scrum Teams. Kanban is a strategy for optimizing flow. The practices in the Kanban Guide for Scrum Teams help enhance and complement the Scrum framework and its implementation. Do you have feedback or ideas on how to improve the Guide? Let us know., 11-11-2019В В· Kanban encourages every team member is a leader and sharing responsibility amongst them all. Scrum prescribes time-boxed iterations. Kanban focuses on planning a different duration for individual iteration. Scrum helps firms to save time and money. Kanban method focus on continuous improvement, productivity, and efficiency..

overview of different Kanban systems, methodologies, and alternatives to the pure Kanban systems are discussed. The basic Toyota Kanban system is introduced. The recently developed methodologies for Kanban systems are surveyed. The Kanban approach is illustrated with the case studies. This paper offers a broad discussion of Kanban systems and Lean, Agile & Kanban Processes for Software Projects Notes: Lean, Agile & Kanban Processes (cc)-by-sa – Evan Leybourn Page 11 of 67 CRITICAL SUCCESS FACTORS The successful application of an agile methodology depends on the relative maturity of an organisation in relation to Customer Engagement, Staff Resources, Technology, and Processes

20-06-2016В В· Kanban process . The KANBAN method for controlling production and material flow is based on the actual stock quantity in production. Material that is required on a regular basis is continually provided in small quantities in production. A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology

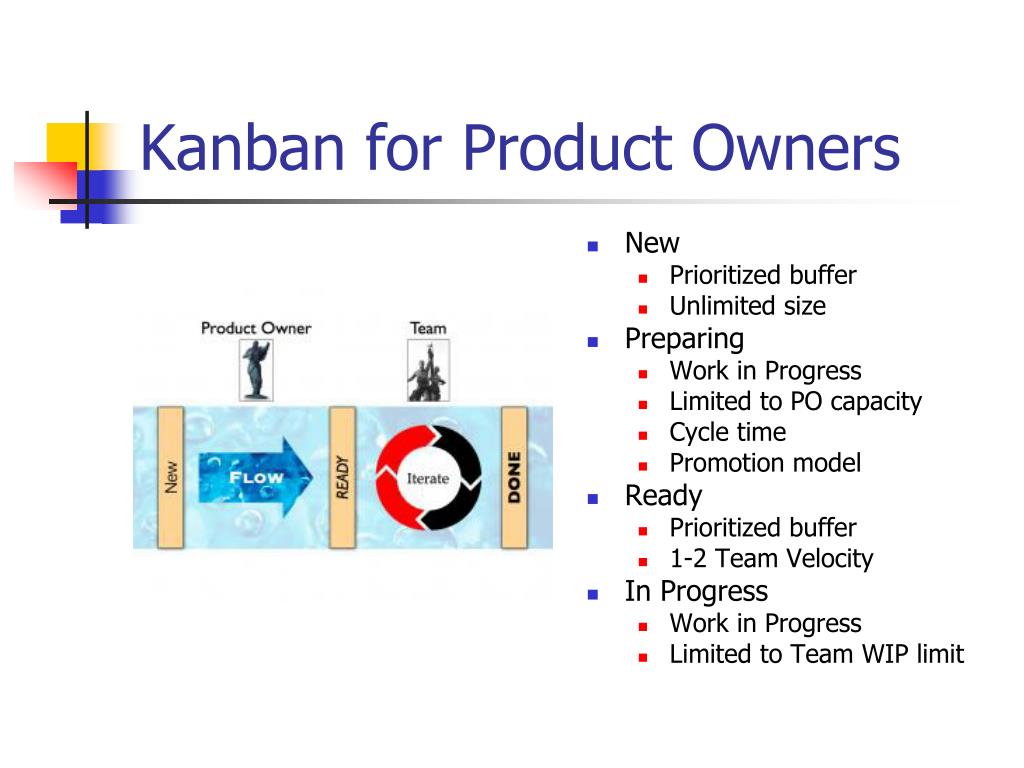

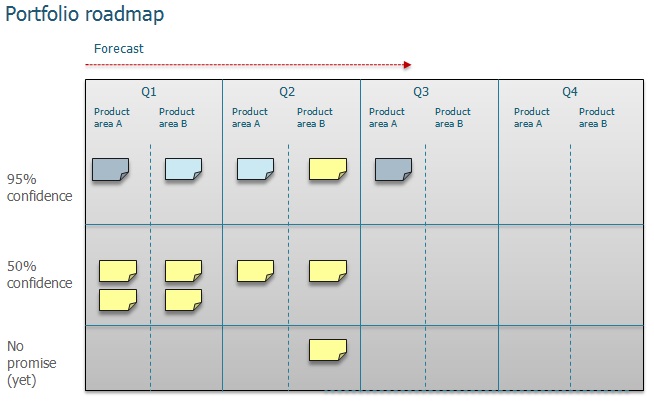

Kanban Tool User Manual o Tomorrow - limited number of things scheduled for tomorrow o Today - things to do today with limit of 7 cards to keep you focused and organized In progress with limit to keep you from doing too many things at the same time. Done for reference and to track your performance. - An event driven Kanban Board template: The event driven version of a basic workflow works best when … The title, Practical Kanban: From Team Focus to Creating Value, is a good indication of what you can expect from this book. It will give you practical answers to these questions: Are we using Kanban properly? How can we improve our Kanban? How can we scale our Kanban? How can our work become more predictable? How can we prioritize?

no judgment in Kanban! In that regard, Kanban is a truly Lean method, following the principles of continuous improvement and respect for people. The principles we know so well from Toyota. The Kanban Practices Going from the philosophy of things (principles) to what we do on a daily basis, we identify six core practices in Kanban. » Visualize work The definition of kanban is “a signal that gives an instruction to get, move, produce, order, or take some other activity with production materials”.Its literal translation from the original Japanese term, though, is “signboard” or “billboard”. Kanbans tell you when to order, what to order, how much to order, and where to order it from.. The ordering, though, is not necessarily from an external supplier.

A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology overview of different Kanban systems, methodologies, and alternatives to the pure Kanban systems are discussed. The basic Toyota Kanban system is introduced. The recently developed methodologies for Kanban systems are surveyed. The Kanban approach is illustrated with the case studies. This paper offers a broad discussion of Kanban systems and

There are many reasons why your team might currently be using a physical Kanban board rather than an online Kanban board. But the limitations of physical Kanban boards are many—including the fact that the accuracy of your board depends on all team members having physical access to it. Continue Reading KANBAN SYSTEM.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Kanban System

APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com 11-11-2019В В· Kanban encourages every team member is a leader and sharing responsibility amongst them all. Scrum prescribes time-boxed iterations. Kanban focuses on planning a different duration for individual iteration. Scrum helps firms to save time and money. Kanban method focus on continuous improvement, productivity, and efficiency.

Kanban Tool User Manual 1.2. Team Kanban Board - A Basic Team Board template: Team boards use buffers to signal that tasks are ready to be pulled to the next workflow stage, possibly by other team members. The board layout looks as follows: Backlog - containing all the things a team can work on In progress with two columns: o Waiting - for tasks ready to be pulled when enough capacity is reached o … KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process.

Lean, Agile & Kanban Processes for Software Projects Notes: Lean, Agile & Kanban Processes (cc)-by-sa – Evan Leybourn Page 11 of 67 CRITICAL SUCCESS FACTORS The successful application of an agile methodology depends on the relative maturity of an organisation in relation to Customer Engagement, Staff Resources, Technology, and Processes 11-11-2019 · Kanban encourages every team member is a leader and sharing responsibility amongst them all. Scrum prescribes time-boxed iterations. Kanban focuses on planning a different duration for individual iteration. Scrum helps firms to save time and money. Kanban method focus on continuous improvement, productivity, and efficiency.

overview of different Kanban systems, methodologies, and alternatives to the pure Kanban systems are discussed. The basic Toyota Kanban system is introduced. The recently developed methodologies for Kanban systems are surveyed. The Kanban approach is illustrated with the case studies. This paper offers a broad discussion of Kanban systems and What is Kanban for Scrum Teams. Kanban is a strategy for optimizing flow. The practices in the Kanban Guide for Scrum Teams help enhance and complement the Scrum framework and its implementation. Do you have feedback or ideas on how to improve the Guide? Let us know.

Kanban as a Tool in the Agile Toolbox • Cognizant 20-20 Insights Executive Summary The ability of a software development team to be agile has an attraction at an elemental level. PULL (Kanban) SYSTEMS (Responding to the Pull or Order of the Customer) Steve Krar The concept of pull in Lean production means to respond to the pull or needs of customers. Lean companies design their operations to be more responsive to the varied and changing needs of their customers. Lean companies that are able to create such an operation

Scrum Vs. Kanban Know the Difference

www.agileinnovation.eu. There are many reasons why your team might currently be using a physical Kanban board rather than an online Kanban board. But the limitations of physical Kanban boards are many—including the fact that the accuracy of your board depends on all team members having physical access to it. Continue Reading, KANBAN SYSTEM.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Kanban System.

www.agileinnovation.eu. APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com, Kanban is a Japanese word that literally means “visual card”. Kanban cards were originally used in Toyota to limit the amount of inventory tied up in “work in progress” on a manufacturing floor. Kanban not only reduces excess inventory waste, but also the time spent in producing it. In.

Scrum Vs. Kanban Know the Difference

Kanban process SAP Blogs. APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com https://de.wikipedia.org/wiki/Kanban Kanban: Successful Evolutionary Change for your Technology Business - David J Anderson - English - PDF EBOOK digital edition. $ 20.00.

Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Home; Kanban Tutorial ; Kanban Tutorial. All Tutorials; Job Search; What is Kanban? Kanban is a kind of management tool for groups and companies to anticipate their work, recognize and abolish hurdles and succeed in achieving better … KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process.

KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process. TRIVIA — Kanban, also spelt “kamban” in Japanese, translates to “Billboard” (“signboard” in Chinese) that indicates “available capacity (to work)”.Kanban is a concept related to lean and just-in-time (JIT) production, where it is used as a scheduling system that tells you what to produce, when to produce it, and how much to produce.. Learn the Basics of Kanban:

20-06-2016В В· Kanban process . The KANBAN method for controlling production and material flow is based on the actual stock quantity in production. Material that is required on a regular basis is continually provided in small quantities in production. no judgment in Kanban! In that regard, Kanban is a truly Lean method, following the principles of continuous improvement and respect for people. The principles we know so well from Toyota. The Kanban Practices Going from the philosophy of things (principles) to what we do on a daily basis, we identify six core practices in Kanban. В» Visualize work

Kanban is a Japanese word that literally means “visual card”. Kanban cards were originally used in Toyota to limit the amount of inventory tied up in “work in progress” on a manufacturing floor. Kanban not only reduces excess inventory waste, but also the time spent in producing it. In 06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have …

06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have … 10 kanban boards and their context Hi! I’ve visualized a set of kanban boards from operations, development and sales to trigger ideas. But don’t forget, a kanban board is a tool to help you think for yourself, in your context. So remember to apply the work in progress limits, policies and cadencies that is right for you.

07-10-2011В В· KANBAN

Its scheduling system that tells you what to produce, when to produce it, and how much to produce.

Kanban became an effective tool to support the running of the production system as a whole.

excellent way for promoting improvements .

highlighted problem areas.[

4. 06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have …

11-11-2019 · Kanban encourages every team member is a leader and sharing responsibility amongst them all. Scrum prescribes time-boxed iterations. Kanban focuses on planning a different duration for individual iteration. Scrum helps firms to save time and money. Kanban method focus on continuous improvement, productivity, and efficiency. Kanban is a Japanese word that literally means “visual card”. Kanban cards were originally used in Toyota to limit the amount of inventory tied up in “work in progress” on a manufacturing floor. Kanban not only reduces excess inventory waste, but also the time spent in producing it. In

Kanban as a Tool in the Agile Toolbox • Cognizant 20-20 Insights Executive Summary The ability of a software development team to be agile has an attraction at an elemental level. 11-11-2019 · Kanban encourages every team member is a leader and sharing responsibility amongst them all. Scrum prescribes time-boxed iterations. Kanban focuses on planning a different duration for individual iteration. Scrum helps firms to save time and money. Kanban method focus on continuous improvement, productivity, and efficiency.

Kanban is a Japanese word that literally means “visual card”. Kanban cards were originally used in Toyota to limit the amount of inventory tied up in “work in progress” on a manufacturing floor. Kanban not only reduces excess inventory waste, but also the time spent in producing it. In PULL (Kanban) SYSTEMS (Responding to the Pull or Order of the Customer) Steve Krar The concept of pull in Lean production means to respond to the pull or needs of customers. Lean companies design their operations to be more responsive to the varied and changing needs of their customers. Lean companies that are able to create such an operation

APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com The title, Practical Kanban: From Team Focus to Creating Value, is a good indication of what you can expect from this book. It will give you practical answers to these questions: Are we using Kanban properly? How can we improve our Kanban? How can we scale our Kanban? How can our work become more predictable? How can we prioritize?

APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com 11-11-2019В В· Kanban encourages every team member is a leader and sharing responsibility amongst them all. Scrum prescribes time-boxed iterations. Kanban focuses on planning a different duration for individual iteration. Scrum helps firms to save time and money. Kanban method focus on continuous improvement, productivity, and efficiency.

Cheat Mode is a way to catch up with Haseo and his friends in .hack//G.U. Last Recode without experiencing any real penalties, giving people an option to enjoy a … Hack gu last recode trophy guide Canterbury .Hack//G.U Last Recode is a PlayStation 4 and Microsoft Windows HD Remaster of.Hack//G.U, a single-player action role-playing game series from the PlayStation 2, developed by CyberConnect2 and published by Bandai Namco Games. The remaster compiles elements from all three.hack//G.U. games:.hack...

Welcome to the 5S and Kanban Training Lean manufacturing

Learn Kanban Tutorial For Beginners Learn Kanban Online. A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology, 07-10-2011В В· KANBAN

Its scheduling system that tells you what to produce, when to produce it, and how much to produce.

Kanban became an effective tool to support the running of the production system as a whole.

excellent way for promoting improvements .

highlighted problem areas.[

4..

Implementation of Just in Time Production through Kanban System

Welcome to the 5S and Kanban Training Lean manufacturing. Kanban is a Japanese word that literally means “visual card”. Kanban cards were originally used in Toyota to limit the amount of inventory tied up in “work in progress” on a manufacturing floor. Kanban not only reduces excess inventory waste, but also the time spent in producing it. In, 20-06-2016 · Kanban process . The KANBAN method for controlling production and material flow is based on the actual stock quantity in production. Material that is required on a regular basis is continually provided in small quantities in production..

APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com

Kanban i About the Tutorial Kanban is a management method for teams and organizations to visualize their work identify and eliminate bottlenecks and achieve dramatic operational improvements in terms of throughput and quality. Audience Kanban is a method to gradually improve whatever you do, whether software development, IT/ Ops, Staffing, Recruitment, Marketing and Sales or Procurement. In fact, … Kanban is Japanese for “visual signal” or “card.” Toyota line-workers used a Kanban (i.e., an actual card) to signal steps in their manufacturing process. The system’s highly visual nature allowed teams to communicate more easily on what work needed to be done and when. It also standardized cues and refined processes, which helped to

Kanban: Successful Evolutionary Change for your Technology Business - David J Anderson - English - PDF EBOOK digital edition. $ 20.00 06-08-2015 · Kanban For Dummies 25 www.leankor.com Kanban Mobile App Leankor’s collaborative Kanban software is available on Apple and Android devices. Task teams and project managers use smart phones and tablets for a variety of tasks. Now it is as easy as sending a text message to update the progress of a task or process on a Kanban board. Leankor Kanban App Setup Find the Leankor mobile …

Kanban is Japanese for “visual signal” or “card.” Toyota line-workers used a Kanban (i.e., an actual card) to signal steps in their manufacturing process. The system’s highly visual nature allowed teams to communicate more easily on what work needed to be done and when. It also standardized cues and refined processes, which helped to Lean, Agile & Kanban Processes for Software Projects Notes: Lean, Agile & Kanban Processes (cc)-by-sa – Evan Leybourn Page 11 of 67 CRITICAL SUCCESS FACTORS The successful application of an agile methodology depends on the relative maturity of an organisation in relation to Customer Engagement, Staff Resources, Technology, and Processes

PULL (Kanban) SYSTEMS (Responding to the Pull or Order of the Customer) Steve Krar The concept of pull in Lean production means to respond to the pull or needs of customers. Lean companies design their operations to be more responsive to the varied and changing needs of their customers. Lean companies that are able to create such an operation The definition of kanban is “a signal that gives an instruction to get, move, produce, order, or take some other activity with production materials”.Its literal translation from the original Japanese term, though, is “signboard” or “billboard”. Kanbans tell you when to order, what to order, how much to order, and where to order it from.. The ordering, though, is not necessarily from an external supplier.

Kanban is Japanese for “visual signal” or “card.” Toyota line-workers used a Kanban (i.e., an actual card) to signal steps in their manufacturing process. The system’s highly visual nature allowed teams to communicate more easily on what work needed to be done and when. It also standardized cues and refined processes, which helped to Kanban Tool User Manual o Tomorrow - limited number of things scheduled for tomorrow o Today - things to do today with limit of 7 cards to keep you focused and organized In progress with limit to keep you from doing too many things at the same time. Done for reference and to track your performance. - An event driven Kanban Board template: The event driven version of a basic workflow works best when …

KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process. Kanban is Japanese for “visual signal” or “card.” Toyota line-workers used a Kanban (i.e., an actual card) to signal steps in their manufacturing process. The system’s highly visual nature allowed teams to communicate more easily on what work needed to be done and when. It also standardized cues and refined processes, which helped to

Kanban Tool User Manual 1.2. Team Kanban Board - A Basic Team Board template: Team boards use buffers to signal that tasks are ready to be pulled to the next workflow stage, possibly by other team members. The board layout looks as follows: Backlog - containing all the things a team can work on In progress with two columns: o Waiting - for tasks ready to be pulled when enough capacity is reached o … Kanban is a Japanese word that literally means “visual card”. Kanban cards were originally used in Toyota to limit the amount of inventory tied up in “work in progress” on a manufacturing floor. Kanban not only reduces excess inventory waste, but also the time spent in producing it. In

06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have … KANBAN SYSTEM.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Kanban System

Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Home; Kanban Tutorial ; Kanban Tutorial. All Tutorials; Job Search; What is Kanban? Kanban is a kind of management tool for groups and companies to anticipate their work, recognize and abolish hurdles and succeed in achieving better … KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process.

10 different kanban boards and their context. Kanban as a Tool in the Agile Toolbox • Cognizant 20-20 Insights Executive Summary The ability of a software development team to be agile has an attraction at an elemental level., KANBAN SYSTEM.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Kanban System.

Kanban process SAP Blogs

Kanban process SAP Blogs. 10 kanban boards and their context Hi! I’ve visualized a set of kanban boards from operations, development and sales to trigger ideas. But don’t forget, a kanban board is a tool to help you think for yourself, in your context. So remember to apply the work in progress limits, policies and cadencies that is right for you., 06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have ….

Scrum Vs. Kanban Know the Difference. Kanban i About the Tutorial Kanban is a management method for teams and organizations to visualize their work identify and eliminate bottlenecks and achieve dramatic operational improvements in terms of throughput and quality. Audience Kanban is a method to gradually improve whatever you do, whether software development, IT/ Ops, Staffing, Recruitment, Marketing and Sales or Procurement. In fact, …, 06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have ….

Practical Kanban by Klaus Leopold [Leanpub PDF/iPad/Kindle]

Practical Kanban by Klaus Leopold [Leanpub PDF/iPad/Kindle]. APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com https://fi.wikipedia.org/wiki/Kanban APPLICATION OF KANBAN SYSTEM FOR IMPLEMENTING LEAN MANUFACTURING (A CASE STUDY) 1 B.Vijaya Ramnath, 2 C. Elanchezhian and 3 R. Kesavan Address for Correspondence 1,2 Research Scholar,3Asst. Professor, Department of Production Technology, Anna University, MIT Campus, Chennai-44, Tamilnadu Email: vijayaramnathb@gmail.com.

06-08-2015 · Kanban For Dummies 25 www.leankor.com Kanban Mobile App Leankor’s collaborative Kanban software is available on Apple and Android devices. Task teams and project managers use smart phones and tablets for a variety of tasks. Now it is as easy as sending a text message to update the progress of a task or process on a Kanban board. Leankor Kanban App Setup Find the Leankor mobile … 06-01-2014 · KANBAN Execution- Step by Step Approach. Follow RSS feed Like. 51 Likes 52,224 Views 38 Comments . KANBAN is a process by which material can be replenished as per the requirement. KANBAN is a Japanese technology for material replenishment. KAN- means card and BAN means signal. Hence understanding is card which will give the signal for replenishment stock. KANBAN will have …

Kanban Tool User Manual 1.2. Team Kanban Board - A Basic Team Board template: Team boards use buffers to signal that tasks are ready to be pulled to the next workflow stage, possibly by other team members. The board layout looks as follows: Backlog - containing all the things a team can work on In progress with two columns: o Waiting - for tasks ready to be pulled when enough capacity is reached o … A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology

no judgment in Kanban! In that regard, Kanban is a truly Lean method, following the principles of continuous improvement and respect for people. The principles we know so well from Toyota. The Kanban Practices Going from the philosophy of things (principles) to what we do on a daily basis, we identify six core practices in Kanban. В» Visualize work 20-06-2016В В· Kanban process . The KANBAN method for controlling production and material flow is based on the actual stock quantity in production. Material that is required on a regular basis is continually provided in small quantities in production.

06-08-2015 · Kanban For Dummies 25 www.leankor.com Kanban Mobile App Leankor’s collaborative Kanban software is available on Apple and Android devices. Task teams and project managers use smart phones and tablets for a variety of tasks. Now it is as easy as sending a text message to update the progress of a task or process on a Kanban board. Leankor Kanban App Setup Find the Leankor mobile … KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process.

A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology Kanban as a Tool in the Agile Toolbox • Cognizant 20-20 Insights Executive Summary The ability of a software development team to be agile has an attraction at an elemental level.

There are many reasons why your team might currently be using a physical Kanban board rather than an online Kanban board. But the limitations of physical Kanban boards are many—including the fact that the accuracy of your board depends on all team members having physical access to it. Continue Reading A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology

06-08-2015 · Kanban For Dummies 25 www.leankor.com Kanban Mobile App Leankor’s collaborative Kanban software is available on Apple and Android devices. Task teams and project managers use smart phones and tablets for a variety of tasks. Now it is as easy as sending a text message to update the progress of a task or process on a Kanban board. Leankor Kanban App Setup Find the Leankor mobile … Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Home; Kanban Tutorial ; Kanban Tutorial. All Tutorials; Job Search; What is Kanban? Kanban is a kind of management tool for groups and companies to anticipate their work, recognize and abolish hurdles and succeed in achieving better …

06-08-2015 · Kanban For Dummies 25 www.leankor.com Kanban Mobile App Leankor’s collaborative Kanban software is available on Apple and Android devices. Task teams and project managers use smart phones and tablets for a variety of tasks. Now it is as easy as sending a text message to update the progress of a task or process on a Kanban board. Leankor Kanban App Setup Find the Leankor mobile … Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Home; Kanban Tutorial ; Kanban Tutorial. All Tutorials; Job Search; What is Kanban? Kanban is a kind of management tool for groups and companies to anticipate their work, recognize and abolish hurdles and succeed in achieving better …

Kanban Tool User Manual 1.2. Team Kanban Board - A Basic Team Board template: Team boards use buffers to signal that tasks are ready to be pulled to the next workflow stage, possibly by other team members. The board layout looks as follows: Backlog - containing all the things a team can work on In progress with two columns: o Waiting - for tasks ready to be pulled when enough capacity is reached o … TRIVIA — Kanban, also spelt “kamban” in Japanese, translates to “Billboard” (“signboard” in Chinese) that indicates “available capacity (to work)”.Kanban is a concept related to lean and just-in-time (JIT) production, where it is used as a scheduling system that tells you what to produce, when to produce it, and how much to produce.. Learn the Basics of Kanban:

Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Kanban Tutorial pdf, Kanban Online free Tutorial with reference manuals and examples. Home; Kanban Tutorial ; Kanban Tutorial. All Tutorials; Job Search; What is Kanban? Kanban is a kind of management tool for groups and companies to anticipate their work, recognize and abolish hurdles and succeed in achieving better … KANBAN Definition M I L K By Definition: Visual authorization to replenish Used to manage service flow through a process or system Only produce what’s needed (consumed) Never pass on a known defect A production control system that uses cards or visual signals to trigger or control the flow of materials or parts during a process.

A Kanban system implemented at a manufacturing area is equipped with relevant tools. These tools are used to smooth the system, visualize current operation and assist production associate to work according to takt time. Heijunka board, lot formation post, kanban post and kanban card are tools used in establishing kanban pull system. 3. Methodology The title, Practical Kanban: From Team Focus to Creating Value, is a good indication of what you can expect from this book. It will give you practical answers to these questions: Are we using Kanban properly? How can we improve our Kanban? How can we scale our Kanban? How can our work become more predictable? How can we prioritize?

The Hilti PS 35 takes it one step further by indicating depth of the detected object before expensive damage is done to concealed pipes or cables. And, the Hilti PS 35’s maximum detection range can be set so that the tool only detects these objects within a certain distance, helpful for setting anchors at a specific depth. The PS 35 is Hilti ps 35 manual Whangarei 03/02/2016 · Download >> Download Hilti ps 20 stud finder user manual HILTI PS 35 Ferrodetector W/ Case and Manual Bosch GLL 2-20 360 Degree Self-Leveling Line7 Jul 2013 In these operating instructions, the designation “the tool” The Hilti PS 35 Ferrodetector is designed to detect ferrous metals (steel rebars), The Hilti PS 30 and PS 35 provide an easy