propress manual tool

propress manual tool

The ProPress Manual Tool is a handheld device designed for securely pressing fittings without soldering, offering a faster, cleaner alternative to traditional methods in plumbing and HVAC systems.

1.1 Definition and Purpose

The ProPress Manual Tool is a portable device designed to securely press fittings without soldering, offering a faster and cleaner alternative to traditional methods. Its primary purpose is to create reliable connections in plumbing, HVAC, and refrigeration systems by compressing fittings onto pipes, ensuring leak-free joints. This tool simplifies installation processes, reduces labor time, and eliminates the need for open flames, making it a cost-effective and efficient solution.

1.2 Brief History and Development

The ProPress Manual Tool was developed to revolutionize pipe fitting connections by eliminating soldering. Originating from advancements in press-fit technology, it gained popularity for its efficiency and reliability. Since its introduction, the tool has evolved, with brands like Viega pioneering its development. Its adoption across plumbing, HVAC, and refrigeration systems highlights its versatility and effectiveness in modern installations.

Types of ProPress Manual Tools

The ProPress Manual Tool is available in several types, including Viega PureFlow, IWISS, and FRK, each designed for specific tasks and user preferences.

2.1 Viega PureFlow Press Hand Tool

The Viega PureFlow Press Hand Tool is a compact, lightweight solution designed for tight spaces. It features a 360-degree rotating head for easy access and extendable handles for enhanced comfort. Ideal for pressing fittings on various pipe sizes, this tool ensures secure connections in plumbing and HVAC systems. Its durability and ease of use make it a favorite among professionals and DIYers alike.

2.2 IWISS Manual Pressing Tool

The IWISS Manual Pressing Tool is a cost-effective solution for pressing ProPress fittings, ideal for small to medium-sized projects. Designed for portability and ease of use, it works efficiently with copper tubes and is perfect for those with limited work on piping systems. Its compact design makes it a practical choice for maintenance tasks and small-scale installations.

2.3 FRK Manual Propress Tool

The FRK Manual Propress Tool is a versatile option for no-weld connections, offering a reliable alternative to traditional methods. It is ideal for applications like refrigeration and freezer maintenance, especially with R600a systems. Designed for efficiency, this tool is lightweight and easy to maneuver, making it suitable for professionals and DIYers alike. Its compact design ensures precise connections for smaller pipe sizes, up to 5/16 inches in diameter, and is backed by a utility model patent for its innovative design.

Key Features of ProPress Manual Tools

ProPress Manual Tools feature automatic locking of pressing tongs, ensuring secure connections. They also include a rotating 360-degree head for easy access and extendable handles for enhanced comfort during use.

3.1 Automatic Locking of Pressing Tongs

The ProPress Manual Tool features an automatic locking mechanism for pressing tongs, ensuring a secure and consistent connection. This mechanism eliminates the need for manual adjustment, reducing the risk of loose connections and improving efficiency. The automatic locking system also enhances safety by maintaining a firm grip on fittings during the pressing process, minimizing the chances of slippage or incomplete seals.

3.2 Rotating 360-Degree Head

The ProPress Manual Tool features a rotating 360-degree head, allowing for easy access to fittings in tight spaces. This versatile design enhances ergonomics, enabling professionals to work comfortably in various environments. The rotating head ensures precise alignment and reduces strain, making it ideal for complex plumbing and HVAC tasks. Its flexibility improves efficiency and accuracy during installations.

3.3 Extendable Handles for Comfort

The ProPress Manual Tool features extendable handles designed for enhanced comfort and control. These handles allow professionals to work in tight spaces without strain, ensuring ergonomic operation. The extendable design accommodates various user preferences and work environments, making the tool user-friendly and efficient for extended periods of use. This feature is particularly beneficial in demanding plumbing and HVAC applications.

Applications of ProPress Manual Tools

The ProPress Manual Tool is versatile, commonly used in plumbing systems, HVAC systems, and refrigeration maintenance. It ensures secure and efficient connections across various applications, making it a reliable choice for professionals.

4.1 Plumbing Systems

The ProPress Manual Tool is essential for plumbing systems, enabling quick and secure connections on copper, PEX, and stainless steel pipes. Its efficiency eliminates the need for soldering, reducing installation time and potential fire hazards. Ideal for water supply lines, hydronic heating, and gas systems, it ensures leak-free connections, making it a reliable solution for professionals in the plumbing industry.

4.2 HVAC Systems

The ProPress Manual Tool is widely used in HVAC systems for efficient and secure connections on copper, PEX, and stainless steel pipes. It streamlines installations in hydronic heating, chilled water systems, and refrigeration lines. By eliminating soldering, it reduces installation time and potential fire hazards, ensuring reliable and leak-free connections in demanding environmental control applications.

4.3 Refrigeration and Freezer Maintenance

The ProPress Manual Tool excels in refrigeration and freezer maintenance, enabling quick, secure connections for copper and thin-walled pipes. It is ideal for systems using refrigerants like R600a, ensuring leak-free joints without soldering. The tool’s portability and 360-degree head make it perfect for tight spaces, reducing downtime and ensuring reliable operation in cold storage and refrigeration systems.

Advantages Over Traditional Methods

The ProPress Manual Tool eliminates soldering, reducing time and material costs. It offers faster connections, portability, and consistent results, making it a more efficient and reliable solution.

5.1 Faster Connection Times

The ProPress Manual Tool significantly reduces connection times compared to traditional soldering methods. It enables secure, leak-proof connections in seconds, streamlining workflows and minimizing downtime. Professionals can complete tasks more efficiently, ensuring projects are finished faster and to a higher standard. This tool is ideal for busy environments where time and precision are critical, making it a valuable asset for any workforce.

5.2 No Soldering Required

The ProPress Manual Tool eliminates the need for soldering, making it a cleaner and safer option. Without requiring an open flame, it reduces fire hazards and the risk of burns. This method also avoids solder residue, ensuring a more efficient and precise connection process. It streamlines workflows and is ideal for environments where traditional soldering methods are impractical or prohibited.

5.3 Cost-Effective Solution

The ProPress Manual Tool offers a cost-effective solution by reducing labor costs and material waste. It minimizes the need for expensive soldering materials and reduces downtime, making it a budget-friendly alternative for professionals. Its durability and long-term performance further enhance its economic benefits, providing a reliable investment for various plumbing and HVAC applications.

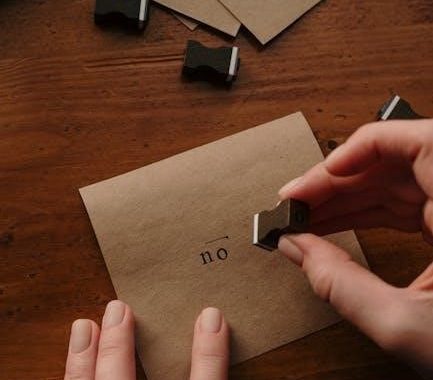

How to Use ProPress Manual Tools

Align the fitting, press firmly until it clicks, and release. The automatic locking mechanism ensures a secure connection every time, making the process efficient and straightforward.

6.1 Step-by-Step Guide

Align the fitting with the pipe, ensuring proper positioning. 2. Place the tool’s jaw around the fitting. 3. Squeeze the handles firmly until a click is heard. 4. Release and inspect the secure connection. This method ensures a quick, reliable press without soldering, ideal for plumbing and HVAC applications.

6.2 Safety Precautions

- Always wear protective gear, including gloves and safety goggles, to prevent injury from tool misuse or debris.

- Ensure the tool is properly maintained to avoid mechanical failure during operation.

- Keep loose clothing or hair tied back to prevent entanglement with moving parts.

- Avoid using damaged or unverified tools, as they may malfunction and cause accidents.

- Operate the tool in a stable, dry environment to maintain control and safety.

Maintenance and Care Tips

Regularly clean and lubricate the tool to ensure smooth operation. Store it in a dry, secure location to prevent damage and maintain longevity.

7.1 Cleaning the Tool

Regularly clean the ProPress manual tool to remove dirt and debris. Use a soft cloth and mild detergent to wipe down surfaces. Avoid harsh chemicals that may damage components. Ensure all moving parts are free from residue to maintain optimal performance and longevity of the tool. Proper cleaning prevents corrosion and ensures precise connections.

7.2 Lubricating Moving Parts

Regularly lubricate the moving parts of your ProPress manual tool to ensure smooth operation. Use a light, silicone-based lubricant to prevent wear and tear. Avoid using petroleum-based oils, as they may attract dust. Apply a small amount to hinges and joints, then wipe off any excess with a clean cloth. Proper lubrication extends the tool’s lifespan and maintains its efficiency.

7.3 Proper Storage

Store your ProPress manual tool in a clean, dry environment to prevent rust or damage. Use a protective case or pouch to safeguard the tool and its components. Ensure all moving parts are clean and lightly lubricated before storage. Avoid exposing the tool to extreme temperatures or moisture. Regularly inspect the tool for any signs of wear or damage during storage. Proper storage ensures optimal performance and longevity. Always follow the manufacturer’s storage guidelines for best results. This helps maintain the tool’s functionality and prevents potential issues when in use. By keeping it in a secure, dry location, you protect your investment and ensure reliability. Regular checks during storage can help identify and address minor issues before they become significant problems. This proactive approach to storage is essential for maintaining the tool’s efficiency and extending its lifespan. Additionally, storing the tool in an organized manner prevents misplacement and ensures it is readily available when needed. Proper storage is a crucial part of tool maintenance, contributing to its overall durability and performance. Always handle the tool with care when placing it in storage to avoid accidental damage. This attention to detail ensures the tool remains in excellent condition for future use. Proper storage practices are vital for maintaining the quality and functionality of your ProPress manual tool, ensuring it continues to perform reliably over time. By adhering to these guidelines, you can maximize the tool’s lifespan and maintain its effectiveness in various applications. Proper storage is an essential aspect of tool care, and neglecting it can lead to unnecessary repairs or replacements. Therefore, it is important to prioritize proper storage to protect your investment and ensure the tool remains in optimal working condition. Always consider the environment and conditions in which the tool is stored, as this directly impacts its longevity and performance. Proper storage is a simple yet effective way to maintain the quality of your ProPress manual tool and ensure it continues to meet your needs. By following these storage tips, you can extend the life of your tool and enjoy consistent performance across various projects and applications. Proper storage is an integral part of maintaining any tool, and the ProPress manual tool is no exception. Always store it in a clean, dry, and secure location to preserve its functionality and ensure it remains a reliable asset for your tasks. Proper storage practices are key to maintaining the tool’s efficiency and preventing potential damage. Always store your ProPress manual tool with care to ensure it continues to serve you well. Proper storage is essential for maintaining the tool’s performance and longevity, making it a crucial step in overall tool maintenance. By storing the tool correctly, you can ensure it remains in excellent condition and continues to deliver reliable results. Proper storage is a simple yet effective way to protect your ProPress manual tool and maintain its quality over time. Always prioritize proper storage to ensure your tool remains in optimal working condition for all your future projects. Proper storage is a vital aspect of tool care, and neglecting it can lead to unnecessary wear and tear. Therefore, it is important to store your ProPress manual tool correctly to maintain its performance and extend its lifespan. Proper storage ensures your tool remains in great condition, ready to handle any task you throw at it. Always store your ProPress manual tool in a clean, dry, and secure location to protect it from damage and ensure it continues to function effectively. Proper storage is an essential part of maintaining your tool’s quality and performance. By following these storage guidelines, you can extend the life of your ProPress manual tool and ensure it remains a valuable asset for years to come. Proper storage is a simple yet effective way to maintain the functionality and longevity of your ProPress manual tool. Always store it in a dry, clean environment, protected from moisture and extreme temperatures, to ensure it continues to perform reliably. Proper storage is crucial for maintaining the tool’s condition and ensuring it remains a reliable tool for your tasks. Always handle the tool with care during storage to avoid any accidental damage. Proper storage is an important step in maintaining the quality and performance of your ProPress manual tool, ensuring it remains a trusted companion for all your projects. By storing the tool correctly, you can protect it from potential damage and extend its lifespan. Proper storage is essential for maintaining the tool’s functionality and ensuring it continues to meet your needs. Always store your ProPress manual tool in a secure, dry location to preserve its condition and performance; Proper storage practices are key to maintaining the tool’s efficiency and preventing unnecessary wear and tear. By adhering to these guidelines, you can ensure your ProPress manual tool remains in excellent condition for years to come. Proper storage is a simple yet effective way to protect your investment and maintain the tool’s reliability. Always prioritize proper storage to ensure your ProPress manual tool continues to deliver outstanding performance. Proper storage is an essential part of tool maintenance, ensuring the tool remains in optimal working condition. Always store your ProPress manual tool in a clean, dry, and secure environment to protect it from damage and ensure it continues to function effectively. Proper storage is crucial for maintaining the tool’s quality and longevity, making it a vital step in overall tool care. By following these storage tips, you can extend the life of your ProPress manual tool and ensure it remains a valuable asset for all your future projects. Proper storage is essential for maintaining the tool’s performance and preventing potential issues. Always store your ProPress manual tool correctly to ensure it continues to serve you well. Proper storage is a simple yet effective way to protect your tool and maintain its functionality over time. Always store your ProPress manual tool in a dry, clean environment, away from moisture and extreme temperatures, to ensure it remains in excellent condition. Proper storage is crucial for maintaining the tool’s efficiency and ensuring it continues to deliver reliable results. By storing the tool correctly, you can extend its lifespan and protect it from unnecessary damage. Proper storage is an important aspect of tool maintenance, ensuring the ProPress manual tool remains a reliable and efficient tool for your tasks. Always store it in a secure, dry location to preserve its condition and performance. Proper storage practices are key to maintaining the tool’s quality and functionality, ensuring it continues to meet your needs. By adhering to these guidelines, you can ensure your ProPress manual tool remains in optimal working condition for years to come. Proper storage is a simple yet effective way to maintain the tool’s performance and extend its lifespan. Always prioritize proper storage to ensure your ProPress manual tool continues to deliver outstanding results. Proper storage is an essential part of tool care, ensuring the tool remains in excellent condition and continues to function reliably. Always store your ProPress manual tool in a clean, dry, and secure location to protect it from damage and ensure it remains a valuable asset for your projects. Proper storage is crucial for maintaining the tool’s quality and longevity, making it a vital step in overall tool maintenance. By following these storage tips, you can extend the life of your ProPress manual tool and ensure it remains a trusted companion for all your tasks. Proper storage is essential for maintaining the tool’s functionality and preventing potential issues. Always store your ProPress manual tool correctly to ensure it continues to serve you well. Proper storage is a simple yet effective way to protect your tool and maintain its performance over time. Always store your ProPress manual tool in a dry, clean environment, protected from moisture and extreme temperatures, to ensure it remains in excellent condition. Proper storage is crucial for maintaining the tool’s efficiency and ensuring it continues to deliver reliable results. By storing the tool correctly, you can extend its lifespan and protect it from unnecessary wear and tear. Proper storage is an important aspect of tool maintenance, ensuring the ProPress manual tool remains a reliable and efficient tool for your tasks. Always store it in a secure, dry location to preserve its condition and performance. Proper storage practices are key to maintaining the tool’s quality and functionality, ensuring it continues to meet your needs. By adhering to these guidelines, you can ensure your ProPress manual tool remains in optimal working condition for years to come. Proper storage is a simple yet effective way to maintain the tool’s performance and extend its lifespan. Always prioritize proper storage to ensure your Pro

User Reviews and Feedback

Users praise the ProPress manual tool for its efficiency and time-saving capabilities, while some criticize durability issues. Others caution against cheaper alternatives, emphasizing the need for quality tools.